Custom Composite

Carbon Fiber is a polymer and is sometimes known as graphite fiber. It is a very strong material that is also very lightweight. Carbon fiber is five-times stronger than steel and twice as stiff. Though carbon fiber is stronger and stiffer than steel, it is lighter than steel; making it the ideal manufacturing material for many parts. These are just a few reasons why carbon fiber is favored by engineers and designers for manufacturing in automotive, aerospace and military.

Your satisfaction is our top priority. We are happy to create an unique product made to your spec and vision.

Custom Body Kits

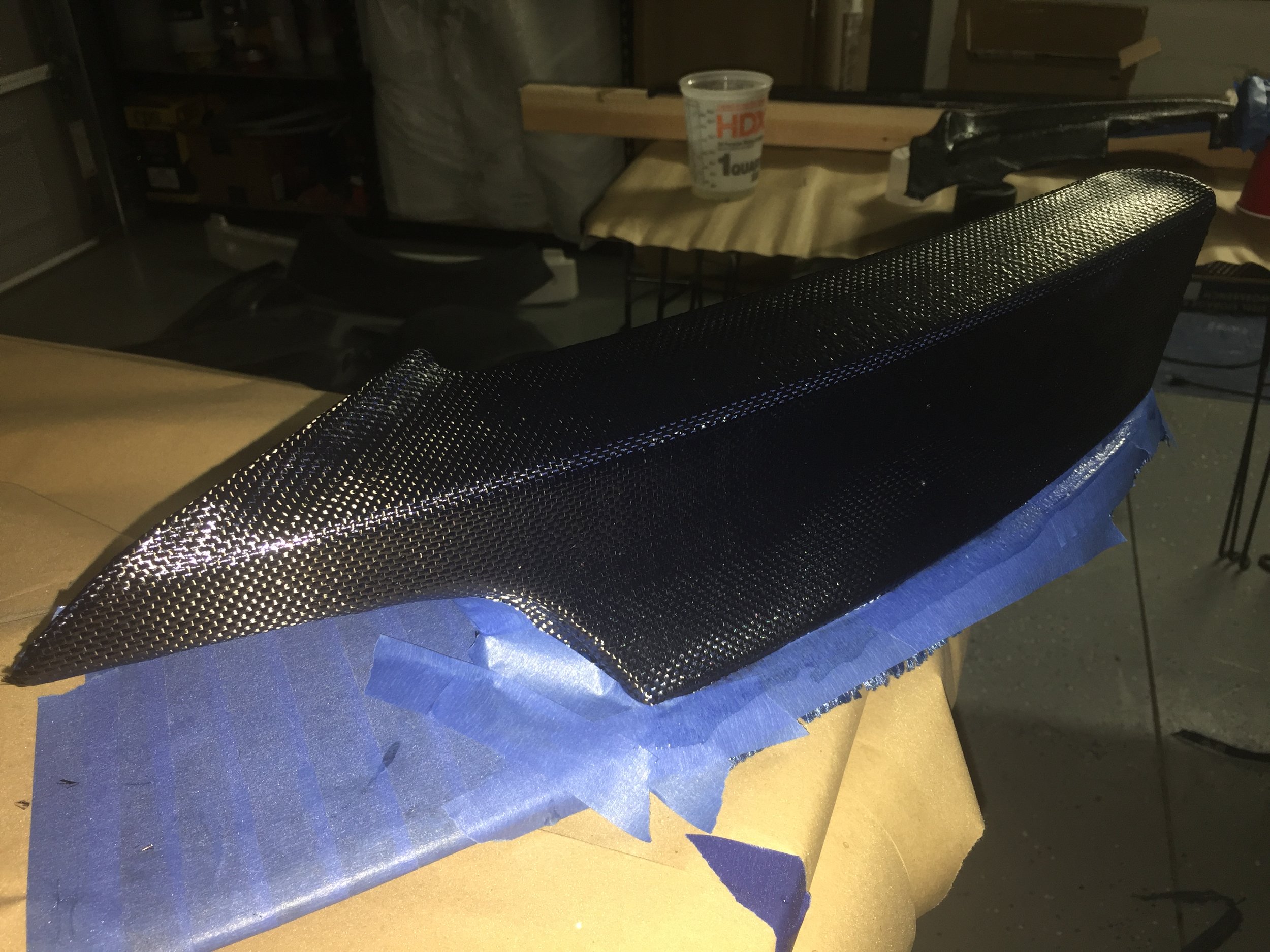

One unique service we provide at Element 6 Design is custom composite.

We are able to produce any kind of carbon fiber/fiber glass parts, our range varies from racing application to interior trim pieces. We can create a one of a kind lip kits that flows with your body line or an aggressive wide body kit to your own specification and vision. We can also modifies existing body kits as well.

There are many factors that need to be in consideration of making a composite parts. Things such as strength, thickness, weight can also be customize-able depending on the purpose of the part.

Carbon also comes in many different forms, the pattern of the weave, color of the carbon and weight of the material.

Composite Parts

Custom parts can be done in hundreds of potential ways. Things like thickness, weight, strength can all vary into different method of producing the parts and the use of different materials.

Often fiberglass products can be just as effective as carbon fiber in terms of weight or strength. It all depends on the applications and the requirements of the parts produced.

There are also many different types of composite weaves such as the popular 2x2 twill, plain weave and new forms such as camo carbon, hex carbon, etc.

With that said, we will communicate with all of our customer to figure out the best option and to create an unique product made to your spec and vision.

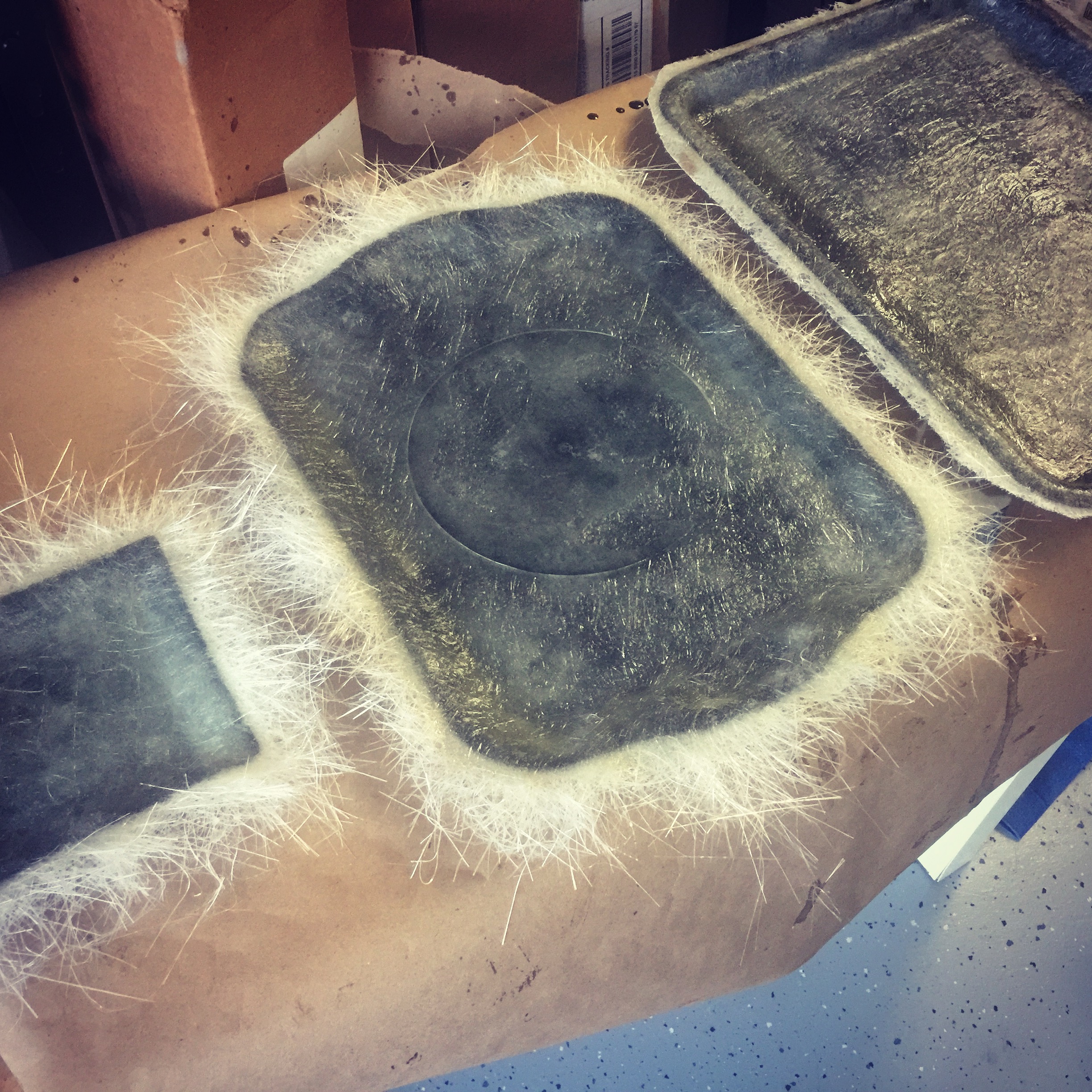

Parts Repair

In many cases composite materials are repairable so there is no need to spend the extra money to purchase it brand new all over again.

Damages such as cracks, chips, stretches and fading are all fixable.

No two repairs are exactly alike; as a result, every repair is considered to be custom and requires special attention.

Carbon Fiber Skinning

Carbon fiber skinning is the process of overlaying existing components with a single layer of real carbon fiber in order to give them a genuine carbon fiber appearance.

When done skillfully it should be impossible to differentiate a part skinning with carbon fiber with one made from 100% carbon fiber.

Whilst skinning is essentially done for cosmetic purposes, the carbon fiber skin will add a tough, durable finish to the original component. Typically the finished layer will add approximately 0.75 mm to the part.

It will also increase the strength and stiffness of the original part. For example, skin of carbon fiber can be added to the top and bottom surfaces of a skateboard deck to increase its stiffness and transform the characteristics of the board.